Industrial, municipal, and military clients often utilize high temperature-resistant fluoroplastic cables because they can handle the intense heat involved in automatic control and measure systems. These systems have wide applications, including everything from electric heating to chemical environments to automotive and aerospace engineering.

The different classifications of Teflon insulated wire inform consumers of their possible use cases. It can include FEP, ETFE, PFA, and PTFE cables. Each classification has different tinsel strengths and resistance to temperatures and chemicals. This resistance ensures you maintain proper connectivity for a wide variety of use or harsh environments.

Teflon is the official brand name of wire made from the PTFE classification. This high temperature resistant wire is often used in environments or cases exceeding 150 degrees Celsius. Some of its more common features include:

1. High-Temperature Resistance

The fluoroplastics used in Teflon insulated wire have exceptional thermal stability, enabling Teflon insulated wire to be used in high-temperature environments of 150 to 200 degrees Celsius. In contrast, the common polyethylene and PVC cables are only suitable for operating at 70 to 90 degrees Celsius. In addition, Teflon insulated wire can transmit larger permitted currents with the same cross-section of conductors, which greatly extends the use of cables.

2. Excellent Flame Retardancy

Fluoroplastics have a high oxygen index. The flame spread of Teflon

insulated wire is slower and produces less smoke. It is used in places and situations where flame retardancy is strictly required, such as computer networks, subways, high-rise buildings, and other public places.

3. Good Electrical Properties

Compared to polyethylene cables, Teflon insulated wire has a lower dielectric constant and less recession, making it more suitable for high-frequency signal transmission. Also, combined with Teflon insulated wire's ability to withstand high temperatures, they are often used as internal wiring and video and audio cables for transmission of communication equipment and control cables for instrumentation.

4. Good Physical and Chemical Properties

Teflon insulated wire has a high degree of stability, is almost unaffected by temperature changes, has excellent weather aging properties and mechanical strength. In addition, Teflon has excellent chemical properties. So it is suitable for applications where there is a great deal of environmental climate change or even corrosive substances, such as petrochemicals, oil refineries, oil well instrumentation control, etc.

Teflon insulated wire is high in demand because of its versatility. In addition, the high thermal stability and flame resistance make it desirable for many industries needing solutions in extreme conditions. It is because of two primary reasons:

PTFE Material - PTFE or polytetrafluoroethylene is a synthetic fluoropolymer. It is hydrophobic, non-wetting, high density, and resistant to incredibly high temperatures. It has a non-reactivity and a high tolerance for extreme temperatures making it perfect for industrial pipes and chemical applications.

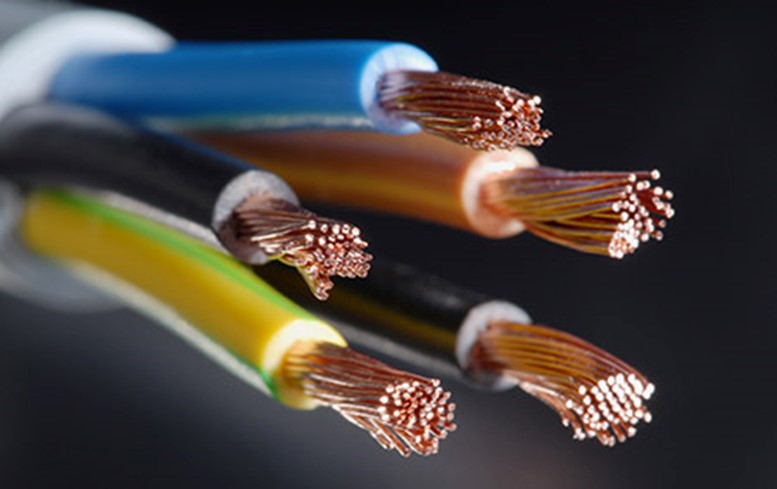

Cable Conductor - the second reason is the conductivity of the platted copper. Customers can pick from tin, nickel, and silver for conductor plating to change the amount of power transmission and connectivity.

Where to use Teflon or PTFE insulated wires, the choices are only limited by your imagination. This type of wire is typically used in industrial settings, but there are so many other possibilities.

PTFE cables provide excellent coverage and protection for medical devices. They also offer solutions for automotive applications where the wire has to be near or on areas of the vehicle where combustion from the engine is present. In addition, many Gas and Oil companies will utilize Teflon insulated wires to prevent diffusion, pressure, and corrosion while drilling.

It comes down to reliability. But, you know, when you select Teflon insulated wires as your material, you will have few concerns about overheating or fire exposure. Instead, the material lends itself to higher temperatures and is especially attractive to those companies needing a solution for wires constantly exposed to moisture, humidity, and liquids.

On top of that, PTFE insulated wires do not deform or creep over time. Once you lay them in place, they will stay there through environmental changes for an incredibly long duration. That makes them a top choice for engineers, manufacturers, and designers needing high-temperature solutions.

Taifulong has provided quality wire and cables to all kinds of industries for decades. Our ability to produce quality tested and verified products from our facilities is why so many of our clients return time and time.

For example, our UL 1213 PTFE insulated wire provides excellent performance in both chemical and harsh outdoor exposures. It retains its properties and heat stability in both high and low temperatures. It is a single-layer wire with flame ratings of VW-1 and FT1 available to all our clients.

To learn more about how Taifulong can transform your next project, reach out to our professional support team. We are willing to deal with any questions or provide solutions for custom orders.

03.17.2022

12.22.2021

11.25.2021

11.01.2021

10.16.2021