PTFE Cable Vs. PFA Cable: Which is Better?

Fluoroplastic insulation cables are used in a wide variety of almost a million things. They are ideal for electronic devices, medical, automotive, wiring, coaxial cables, and home appliances. The best thing about fluoroplastic cables is that they can be used at high temperatures as they don’t quickly melt. There are many types of fluoroplastic cables, namely:

PTFE:

These cables are the most fluorinated, having the best resistance to extreme factors.

PFA:

These cables are similar to PTFE in terms of sound performance, but the only issue is their high price.

FEP:

This is first a cable in which melting fluoropolymer is done. However, they are not as resistant to harsh chemicals and factors as PTFE or PFA.

ETFE:

These cables have better cold-flow resistance, good abrasion resistance, and high tensile strength. But, they are not entirely fluorinated.

PTFE wire or Polytetrafluoroethylene is a fluorocarbon insulation material that helps the wiring system work ideally in the most demanding and extreme environments. This insulation material is resistant to lubricants, chemicals, and fuels. In addition, they have excellent electrical and thermal features and are flexible. Thus, they can easily be used for places and applications which require wiring to be resistant to high levels of chemical and thermal.

They have excellent performance against high temperatures.

Mechanically flexible and tough compared to other insulations.

Great dielectric performance.

Highly resistant to flame, water, and all chemicals.

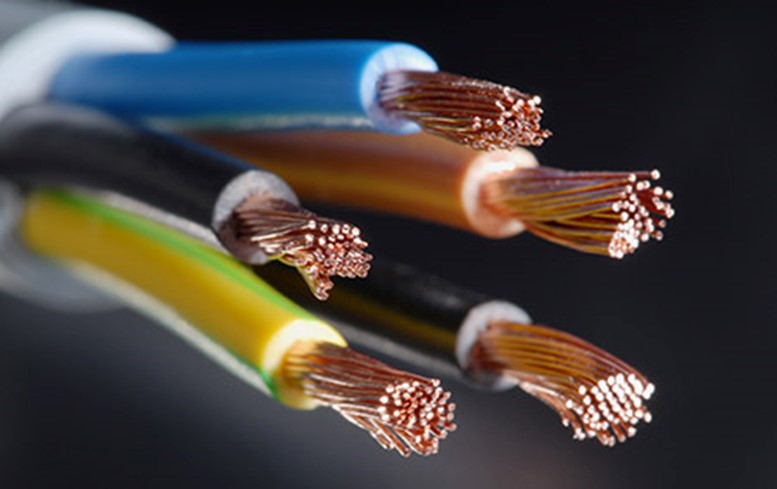

Conductors plated with nickel and silver.

They can bear up to 250/300, 600, and 1000 volts

PTFE wire has excellent non-stick quality.

Translucent color.

Let’s talk about PFA Cables and their advantages now!

PFA wire or Perfluoroalkoxy is a fluoropolymer insulation material having similar properties as PTFE. PFA wire is also very resistant to oils, chemicals, extreme temperatures, and lubricants. These wires are amazingly flexible and also have dielectric power.

However, the only difference is that they are more expensive than PTFE insulation materials.

They are perfect for jackets and insulations.

They can bear temperatures up to -75C to +260C. They remain intact at cryogenic temperatures.

Their conductors are nickel-plated and silver-plated.

PFA wire is available in a range of colors for easy identification.

Light-weight (both for space and weight) and compact.

Have excellent dielectric properties.

These wires have great flexibility.

They are bio-compatible.

Let’s first talk about PTFE Cable features:

Chemical Properties:

Polytetrafluoroethylene has a solid at room temperature. It is a high molecular weight fluorocarbon that consists of fluorine and carbon. Its melting point is 327 C, its density is 2200 kg/m³, and its chemical formulae is (C2F4) n.

Surface Properties:

PTFE has a non-stick surface that is resistant to most chemicals and heat. It is one of the only surfaces on which even a gecko can’t stick.

Electrical Properties:

The inertness and stability of PTFE cables contribute to high electrical resistances and dialectical power. This means that PTFE requires high power to produce the dielectric breakdown. What makes them excellent insulator for cables is their ability to bear the passage of strong electrical current.

Thermal Performance:

PTFE is used in cables because they are resistant to almost everything. They have the best electrical properties and one of the most extensive ranges of plastic materials to bear temperatures from 200C to 400C (but for a short time).

Let’s now talk about PFA Cable features:

Chemical Properties:

PFA is a semi-crystalline fluorinated polymer that, along with temperature resistance, is also non-flammable. They repel oil, water and are resistant to almost all chemicals. Its melting point is 305C.

Surface Properties:

The surface properties of PFA are similar to PTFE. As they are both identical except for one or two modifications, they also have a non-stick and smooth surface resistant to most chemicals and temperatures.

Electrical Properties:

PFA has excellent dialectical properties like surface resistivity and high volume. However, these properties are consistent with different temperatures, which are less than those of PTEF. This makes PFA wires ideal to be used in electric devices.

Thermal Performance:

PFA is suitable for both low and high temperatures. They can be used for temperatures ranging from 268 C- 260 C. and are similar to the thermal performance of PTFE, but they are melt and process-able.

Let’s first talk about PFA Cable applications:

PFA wires can be used for:

Automotive lines, NOx sensors, and oxygen equipment.

Scientific and medical instruments.

Marine systems.

Gas ignitors.

Aircraft and computers.

Electronic and household appliances.

Let’s now talk about the PTFE Cable application:

PTFE wires can be used for:

Oven, heater, and any high-temperature equipment wiring.

Air-field equipment.

High-performing motors, rectifiers, and transformers.

Thermocouple and compensating wiring.

Satellites, radars, and aircraft.

Both PRFE and PFA cables have fantastic features and a wide range of applications. However, they only work best if they are of high quality. Taifulong has been one of the leading international manufacturers of special wire cables since 1989. The wires that Taifulong produces are made with high-quality material for durability, and we at Taifulong annually satisfy up to 900M+ customers with their superior-quality wire and cables.

For more information, please visit Taifulong at: https://taifulong.com/.

03.17.2022

12.22.2021

11.25.2021

11.01.2021

10.16.2021