How to Choose Teflon Insulated Wire with Different Copper Conductors

Teflon insulated wire has changed the industry because of its durability. These are incredibly resistant to fluctuating power, moisture, extreme temperature, and chemical exposure. Not only can they hold up against a wide array of environmental factors, but they are also made to be strong enough to handle even the most strenuous of applications.

You can find Teflon insulated wires in many industries, including everything from the medical field to aerospace technology. A more popular recent application is their use in electronic cars. As the industry grows, it demands broader use of technology and electrical circuitry to handle the dangers of being on the road in any weather. That is why they are using Teflon insulated wire.

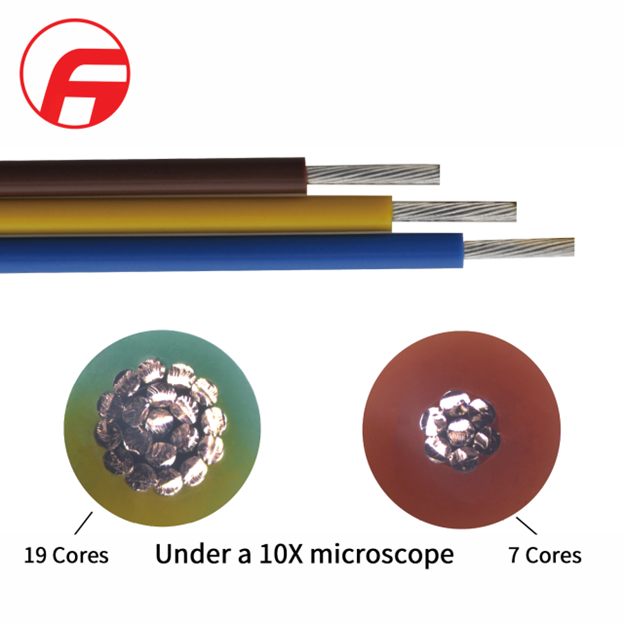

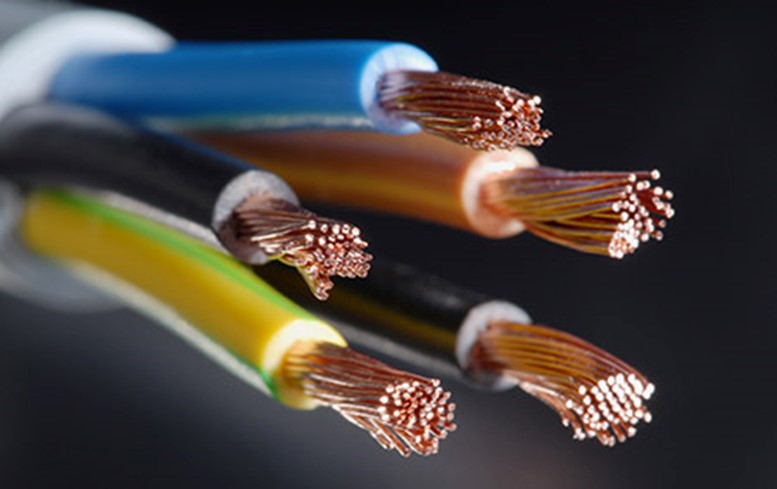

Different Cable Conductor Types of Teflon Insulated Wires

Teflon insulated wires are used in so many wide applications, so they need to have different cable conductor types. It meets the demand of temperature, wear resistance, oxidization, and many more aspects.

Tin-Platted Copper

Tin-platting as a cable conductor prevents copper from being exposed to air, resulting in oxidization. Otherwise, a layer of copper green can form, which increases the wire's electrical resistance. Tin creates stability even in the air at room temperature when the surface generates a dense oxide film that prevents continual oxidation. Placing this outside of copper adds a layer of protection and enhanced electrical conductivity, wear resistance, corrosion resistance, and electromagnetic shielding.

Tin provides a low-cost alternative for cable conductors. Still, it should be noted the temperature resistance is usually only up to 150 degrees Celsius, or 200 degrees Celsius if the conductor diameter is greater than 0.38.

Nickel-Plated Copper

Nickel has a strong passivation ability where the surface can generate a film resistant to corrosion from the atmosphere. The nickel coating provides an extra layer of hardness that improves the wear resistance of the underlying materials. You can expect a temperature resistance of up to 250 degrees Celsius, but it is more expensive than the alternative tin-platting.

Silver-Plated Copper

Silver coating is very easy to polish and has a strong reflective property that is good in thermal and electrical conductivity for improving welding performance and contains a high corrosion resistance. Of all the other cable conductor types, silver-platting is the most expensive. However, it has the best conductor performance, especially in high-frequency use, but not as good temperature resistance as nickel-plated copper.

Where These Conductors Are Utilized

Each of these Teflon-insulated wires has its advantages and similarities. They all provide a wide range of added protection to the underlying copper components in resistance to temperature, corrosion, and enhanced durability.

For example, tin-plated copper conductors have often been used in PFA or PVC cabling. However, PVC's less expensive nature and normal temperature range are often utilized in medical, food, commercial, and household applications. They are combining PVC and PFA wiring with Teflon insulated wires. Tin-plated conductors allow for a bit more temperature resistance range while piggybacking on the added layer, preventing oxidation due to the tin.

Nickel-plated copper is most often in PTFE insulated wires. This form of the cable has to withstand much harsher chemical and temperature conditions. Adding the nickel layer gives you extra hardness that protects and insulates the underlying copper from extreme weather and chemical exposure. That is why you can find this wire in heaters, boilers, ovens, high-performance motors, thermal couplings, satellite equipment, and more.

When you add silver-plating to Teflon insulated wire, you get a highly reflective outer surface designed for the most extreme conditions. The aerospace and medical research fields are two areas where this is widely used due to the strong polish that can increase thermal and electrical conductivity.

Enhancing Your Site with Taifulong Teflon

If you are in the quality Teflon insulated wire market, you should check out Taifulong. We at Taifulong use Teflon with high-temperature resistance and melting point while maintaining thermal stability. It is made with chemically inert materials and is non-flammable, allowing for excellent dielectric strength with a low dielectric constant.

Getting Started with Taifulong

Ordering your Teflon insulated wire from Taifulong is an excellent decision because we have more than 20 years of manufacturing experience with high-temperature wires and cables. We can fulfill customized orders and have worked in medical research to military applications. Taifulong expertise in the field of metal plated wire has led them to be recognized as "National Hi-tech Enterprise" and "Key Industry of Hi-tech in the China Torch Program."

Taifulong is an industry leader in Teflon insulated wire and can help you get the cabling you need to get the job done right so you can get back on track. To schedule a consult, reach out to our intake team through the website at www.taifulong.com ; or kindly contact us by our customer service line at +86-020-8218-0888.

03.17.2022

12.22.2021

11.25.2021

11.01.2021

10.16.2021